Buy with confidence, sleep in peace.

The rise of the digital economy has allowed many, the ease of access to information like never before. Stainless steel products are slowly being commoditized and easily sourced but can buyers truly rest easy after placing an order from a foreign entity that they have never ever met?

Here at HH Group, we strive to work with reputable brands while also staying agile by constantly expanding our sources, we take on the risk in your stead so that you would always have someone trustworthy to be accountable for, someone whom you can trust to always resolve your issues should any arise. Besides surveying the actual factory of production for when we are able to, we have stringent incoming processes to verify the integrity and quality of the materials.

Behind the scenes, our in-house Quality Assurance team verifies all our incoming materials using both visual inspection and Positive Material Identification (PMI) testing, allowing our customers to buy with confidence. In this article, we look to explore the two most common forms of PMI testing that we will explore below:

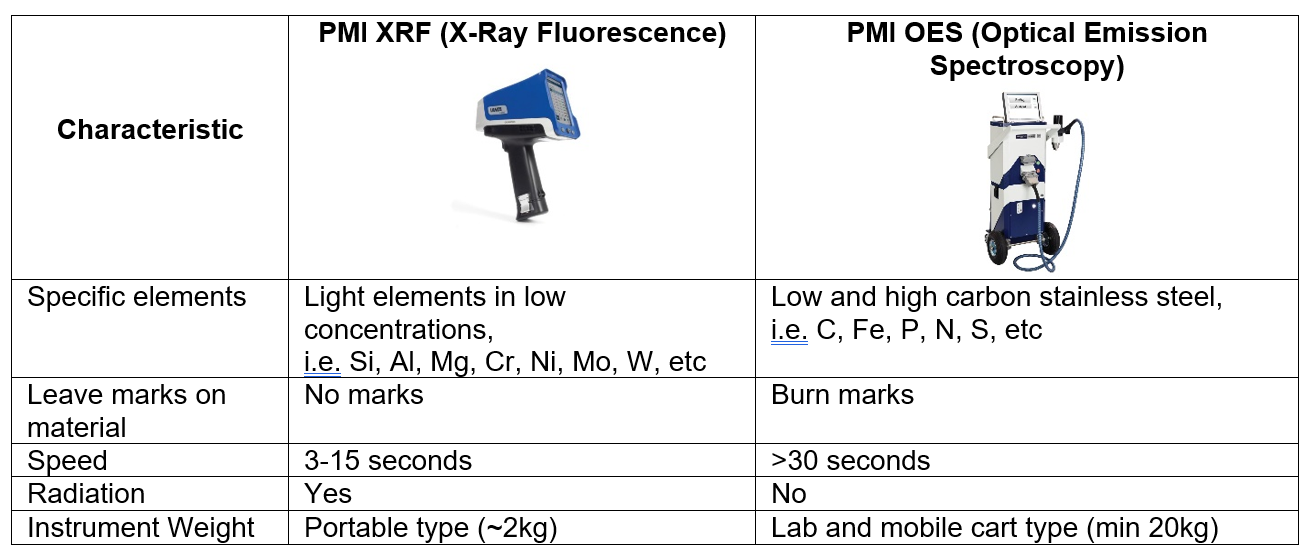

PMI XRF (X-Ray Fluorescence) and OES (Optical Emission Spectroscopy)

The X-ray fluorescence (XRF) is the most commonly used Non-Destructive Test (NDT) method offering the user a portable handheld analyser that delivers fast, accurate results.

The Optical Emission Spectroscopy (OES) is an optical method that can be used to detect almost all types of elements, including carbon and light elements in a variety of different matrixes including stainless steel, nickel, and carbon steel, etc.

Alloy Elements Required for Alloy Verification

The individual alloy elements listed shall be evaluated during PMI testing, based on the specified alloy grade

| Alloy | Chemical Elements |

| 304 | Cr, Ni |

| 316 | Cr, Ni, Mo |

| 310 | Cr, Ni |

| 410 | Cr, Ni, Ti, Al |

| 430 | Cr, Ni |

| 2205 duplex | Cr, Ni, Mo |

| 2507 super duplex | Cr, Ni, Mo |

PMI XRF (X-Ray Fluorescence) vs PMI OES (Optical Emission Spectroscopy)

Limitations on XRF method PMI

With the portability that the XRF handheld devices offer comes a downside in which elements lighter than Magnesium cannot be measured using XRF. This limitation of XRF makes it impossible to grade materials such as low carbon stainless steels, carbon steel, and low alloy materials because Carbon cannot be measured utilizing XRF analysers.

For example, XRF can measure the elements required to identify 316 stainless steels, but cannot measure the Carbon required to identify whether that same 316 material is L or H grade. Carbon is the essential element required to verify the different grades of stainless steels ie; 316L or 316H.

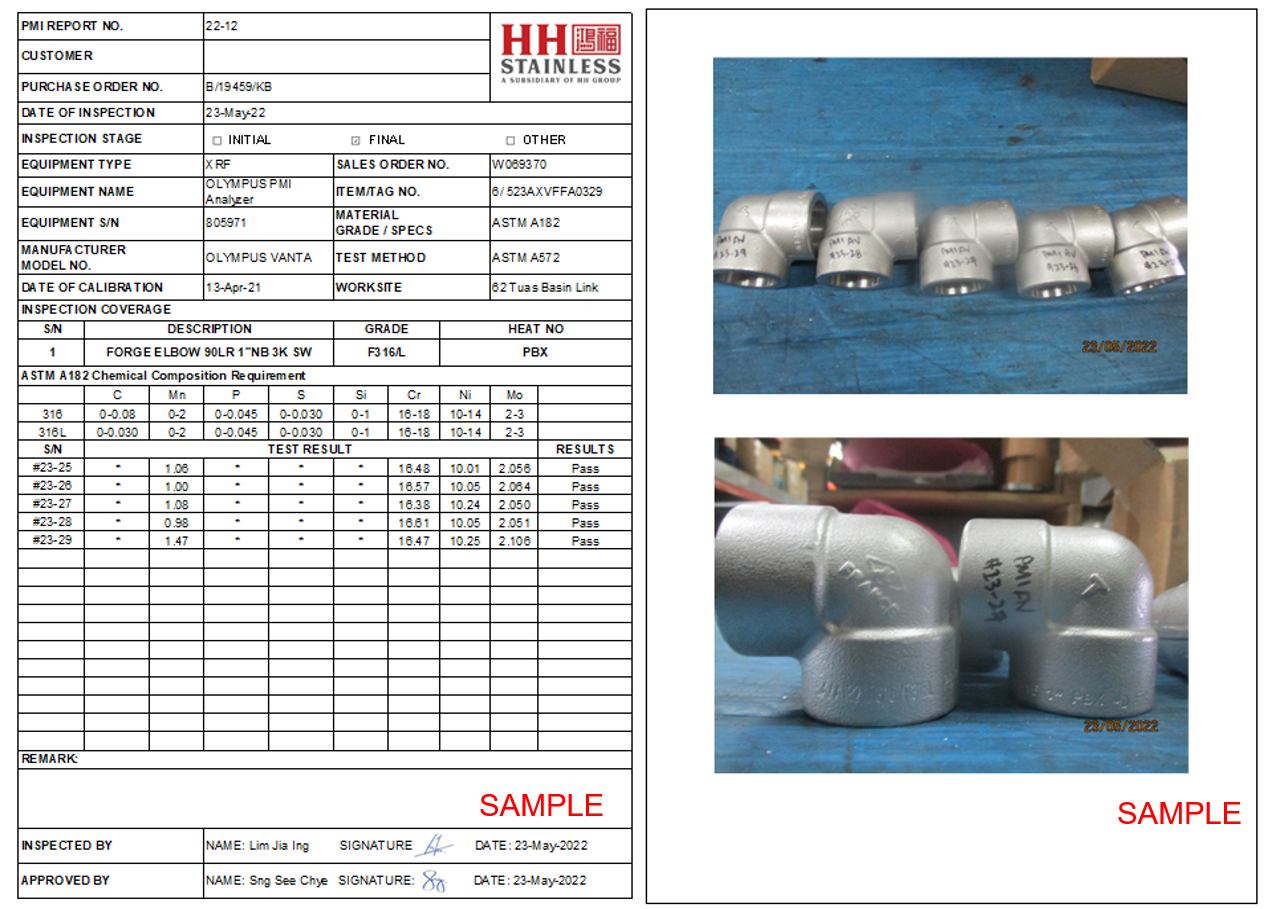

Internal testing method – PMI XRF (X-Ray Fluorescence)

Here at HH Group, we employ the use of XRF analysers to provide fast, accurate chemistry and alloy identification in PMI applications for our materials whether on or off-site.

The alloy XRF principle (X-Ray Fluorescence) is one of the methods for PMI whereby the equipment used, contains low radioactive sources (isotopes) or x-ray tubes. The exposed material reflects the radiation, generating energy.

XRF analysers are able to identify pure metals and alloy grades including:

| · Stainless steels | · Zinc alloys |

| · Chromium-molybdenum steels | · Zirconium alloys |

| · Nickel and nickel/ cobalt alloys | · Titanium alloys |

| · Low alloy steels | · Cobalt alloys |

| · Copper alloys | · Magnesium alloys |

| · Aluminium and wrought aluminium alloys | · Exotic alloys |

Sample of PMI Reporting Format