Description

Forged Flanges

WHAT ARE FLANGES?

Flanges offer a reliable way to connect pipe systems with various equipment, valves and other components to make a pipework system. Using flanges adds flexibility when maintaining piping systems by allowing for easier disassembly and improved access to system components.

A typical flange connection is comprised of three parts:

- Pipe Flange

- Gasket

- Bolting

Typically, flanges are either welded or threaded and two flanges are connected together by bolting them with gaskets to provide a seal that provides easy access to the piping system. These Flanges are available in various types such as slip-on flange, weld neck flange, blind flange, and socket weld flange, etc.

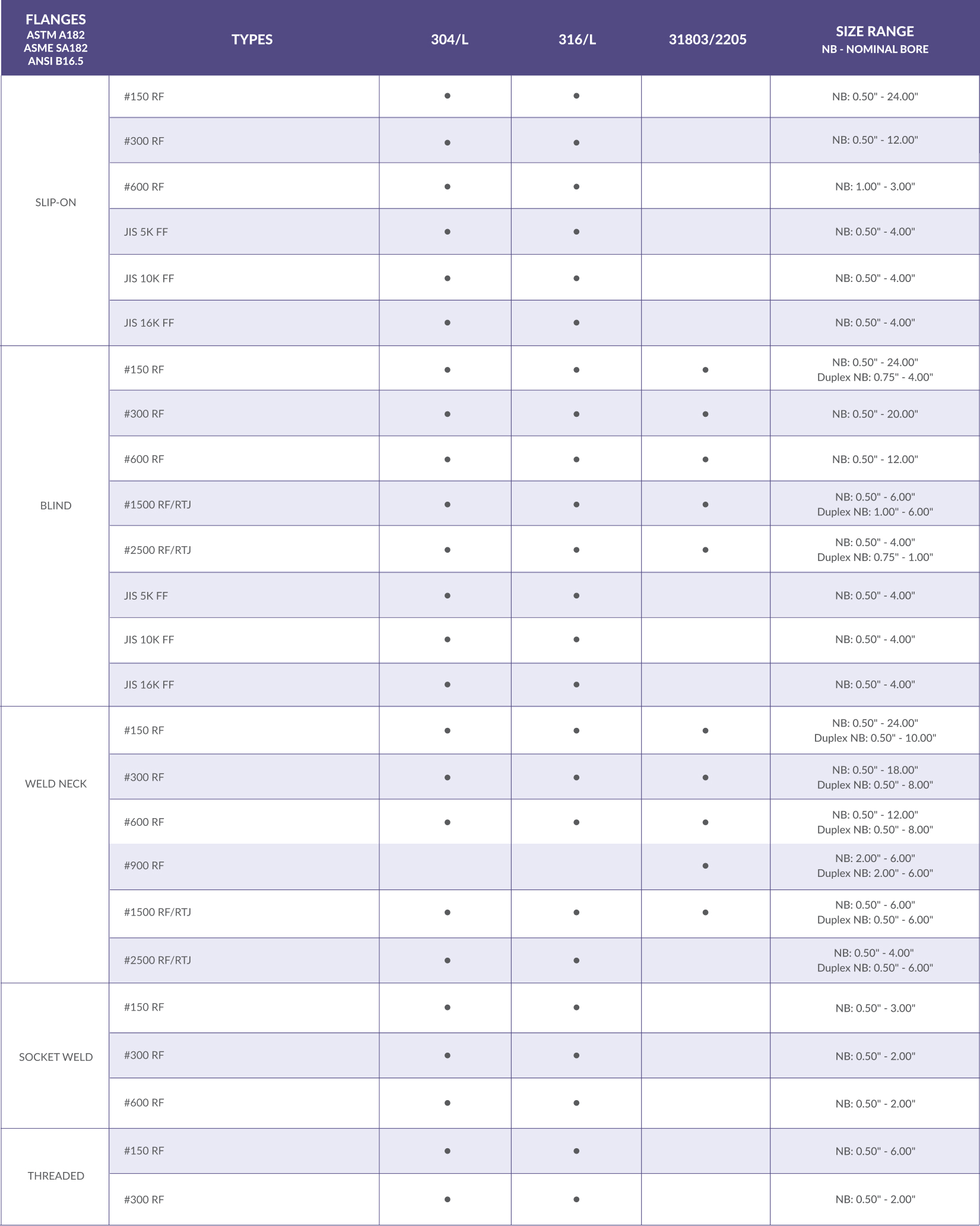

AVAILABLE SIZE RANGE

COMMON TYPES OF FLANGES CLASSIFICATION:

Flanges are often classified based on their ability to withstand temperatures and pressures. This is designated using a number and “#” or “LB” such as 150#, 300# etc. Exact pressure and temperature tolerances will vary by the materials used, flange design and flange size. The only constant is that in all cases, pressure ratings decrease as temperatures rise.

AVAILABLE TYPES

QUALITY ASSURANCE

EXPLORING COMMON TYPES OF FLANGES:

Below, we dive into the common types of flanges one would encounter in their course of usage:

WELDING NECK FLANGE

The welding neck flange is normally referred as the high hub flange due to its long tapered hub that is easily recognizable. The smooth transition from flange thickness to pipe or fitting wall thickness effected by the taper is extremely beneficial, under conditions of repeated bending, caused by line expansion or other variable forces.

These flanges are bored to match the inside diameter of the mating pipe or fitting so there will be no restriction of product flow. This prevents turbulence at the joint and reduces erosion. They also provide excellent stress distribution through the tapered hub and are easily radiographed for flaw detection

This Flange type will be welded to a pipe or fitting with a single full penetration, V weld (buttweld).

SLIP-ON FLANGE

The slip on flange has a low hub to allow the pipe to slip into the flange prior to welding. It is welded both inside and out to provide sufficient strength and to prevent leakages. Slip-on flanges are all bored slightly larger than the outer diameter of the matching pipe.

The connection with the pipe is done via 2 fillet welds, one on the outside and one on the inside of the flange.

SOCKET WELD FLANGE

Socket weld flanges are similar to a slip-on flange except that it has a bore and a counter bore dimension. These are Ideal for smaller pipe diameters in low-temperature and low-pressure scenarios.

The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe. The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap

LAP JOINT STUB END FLANGE

Lap Joint Flanges are practically identical to a slip-on flange in terms of dimensions. It is usually used in conjunction with a stub end as a backing flange hence the commonly used term of Lap Joint Stub End for its naming.

These flanges will be slipped over the pipe and are not welded or fastened to it. This design style is suitable for use in systems that require frequent dismantling or maintenance.

THREADED (SCREWED) FLANGE

The threaded flange is similar to the slip-on flange but the bore is threaded. Its usage stems from the fact that it can be assembled without welding explaining its use in low pressure services.

Threaded flanges are typically used in thicker pipes as cutting thread on a pipe is not feasible.