Description

Sheet & Plates

A SHEET OR A PLATE

One may have heard of clients talking about stainless steel sheets and plates in the same vein which are commonly used interchangeably. We typically classify sheets as having a thickness of 6mm and below but exceptions are made also based on their surface finishes. Commonly No. 1 Surface finishes are referred to as plates due to their main usage as structural components. Both stainless steel sheets and plates have a wide variety of usage in the construction, chemical, oil & gas and many other sectors.

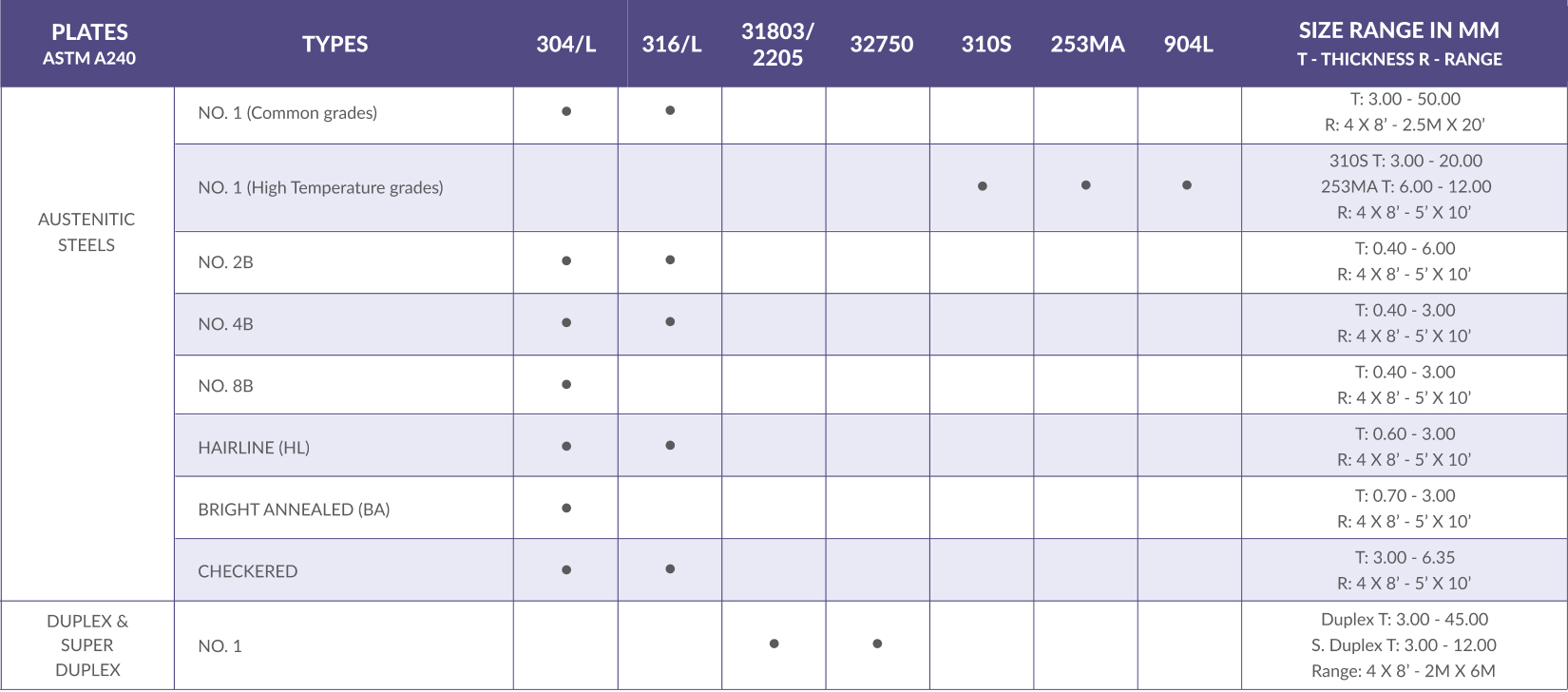

STAINLESS STEEL SHEET & PLATE GRADES:

SS304/L is the most popular grades of stainless steel are namely SS 304 and SS316. SS304 contains 18% Chromium and 8% Nickel and are commonly used worldwide.

SS316/L on the other hand, contains 16% Chromium and 10% Nickel but there is an additional 2% Molybdenum. This addition allows SS316 materials to have increased corrosion resistance as compared to SS304 materials. SS316 materials are favored for use outdoors and nearer to marine and coastal settlements.

SS31803/2205 is also commonly known as duplex stainless steel. This grade is the most popular duplex product on the market which offers good resistance to uniform and localized corrosion and as well as stress corrosion cracking.

SS32750 is a super duplex product with higher corrosive resistance and mechanical strength when compared with SS31803/2205. The PREN of Super Duplex is between 40 to 45. Super duplex has seen increasing usage in the Asia pacific region for usages such as scrubbers.

SS310S is an austenitic heat- and creep-resisting stainless steel with excellent oxidation resistance in mildly cyclic conditions and is best employed in high temperatures up to 1050°C/1920°F.

SS253MA is an austenitic heat-resisting stainless steel with excellent oxidation and creep resistance in cyclic conditions and is best employed in high temperatures up to 1100°C/2012°F. This material grade is trademarked by Outokumpu, of which HH Stainless is a appointed distributor for in the South East Asia Region.

SS904L is an austenitic high alloy stainless steel with low carbon content but with copper being added to improve its resistance to strong reducing acids. It is also resistant to stress corrosion cracking and crevice corrosion.

AVAILABLE FINISHING

QUALITY ASSURANCE

Below we explore the common available finishes in the market. HH stainless stocks the following range but not limited to the following:

NO. 2B FINISH

2B finish plates are a general purpose cold-finished plate that is commonly used globally. 2B plates forms the base of most polished plates as manufacturers use it to polish to the subsequent finishes that you would find below.

The 2B surface itself has a matte-like and smooth surface exterior.

NO. 4B FINISH

4B finish plates go by a variety of names ranging from Satin finish, broken hairline and brushed finish. This is due to its characteristics of having short but parallel polishing lines that extend uniformly across the plate.

The 4B surface itself has a shiny exterior with a myriad of broken up lines in one direction.

NON-DIRECTIONAL (ND) FINISH

Non-directional finish plates have a distinct pattern of fine lines going in multiple directions, hence the term non-directional.

Amongst all the surfaces, this is generally the most “scratch” resistant as scratches can’t be easily seen due to there being multiple different lines in various directions.

BRIGHT ANNEALED (BA) FINISH

Bright Annealed plates are common called bright finished plates. They may be easily mistaken for mirror plates as both are reflective in nature. The main difference between the two is that BA finishes generally exhibit a blurrier reflection as compared to their mirror counterparts.