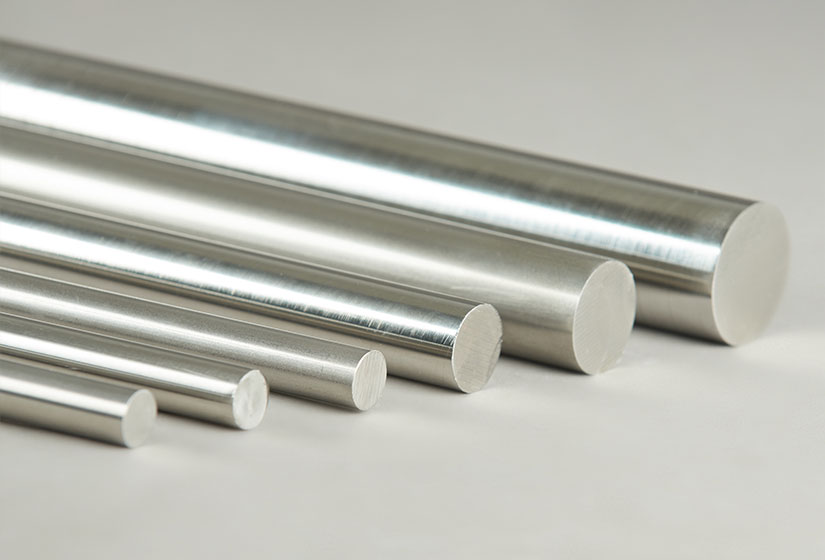

Description

Martensitic Bars

WHAT ARE MARTENSITIC STAINLESS STEELS

Martensitic stainless steel is an alloy which is mainly comprise of chromium with little to no nickel content as compared to their Austenitic Counterpart. Due to its chemical composition, heat and aging treatments can lead to martensitic steel being hardened and strengthened giving it very high abrasion resistance and toughness. Although it is strong but due to the lack of Nickel, Martensitic stainless steel’s corrosion resistance is lower as compared to Austenitic stainless steels.

Martensitic stainless steel can be further broken up into two categories of low and higher carbon variants. High Carbon Martensitic Stainless Steel has a range of 0.61% to 1.50% of carbon content whereas Low Carbon Martensitic Stainless Steel has between 0.05% to 0.25% of carbon content.

AVAILABLE TYPES

QUALITY ASSURANCE

SS410 (UNS S41000)

Stainless Steel 410 is a 12% chromium martensitic stainless steel alloy that can be heat treated to obtain a wide range of mechanical properties via hardening, tempering and polishing. Quenching and tempering leads to an increase in hardness in the right temperatures. These are generally used for applications involving mild corrosion, heat resistance and high strength.

SS431 (UNS 43100)

Stainless steel 431 is a martensitic, heat-treatable grade with excellent corrosion resistance, torque strength, high toughness and tensile properties. All these properties make them ideal for bolt and shaft applications. These steels, however, cannot be cold-worked owing to their high yield strength, hence they are suitable for operations such as spinning, deep drawing, bending or cold heading.

SS440C (UNS S44004)

Stainless steel 440C is a martensitic, heat-treatable grade with one of the highest hardness, strength and wear resistance among the various 440 grades. There are four types available including 440A, 440B and 440F. It has moderate corrosion resistance when compared to other stainless steels, and it exhibits its best corrosion resistance in its hardened and tempered form.

17-4 PH H1075 (UNS S17400)

Stainless Steel 17-4PH is a Precipitation Hardening (PH) martensitic stainless steel which is also known as grade 630 stainless steel. 17-4PH exhibits moderate corrosion resistance and high strength which can be further optimized based on the different heat treatment temperatures it undergoes.

15-5 PH H1075 (UNS S15500)

Stainless Steel 15-5 PH is a Precipitation Hardening (PH) martensitic stainless steel which is also known as XM-12. 15-5PH was developed as a modification to 17-4 PH with a more refined microstructure obtained through the remelting process resulting in improvement in toughness of the material. Both 15-5PH and its predecessor 17-4PH exhibit high strength and moderate corrosion resistance.