Description

Nickel Alloy Bars

WHAT ARE NICKEL ALLOYS?

Nickel will alloy readily with most metals such as copper, chromium, iron and molybdenum. The addition of nickel alters the properties of the resulting alloys that can be used to produce desirable characteristics such as outstanding resistance to corrosion, increase high-temperature scaling, exceptional strength and many other unique properties.

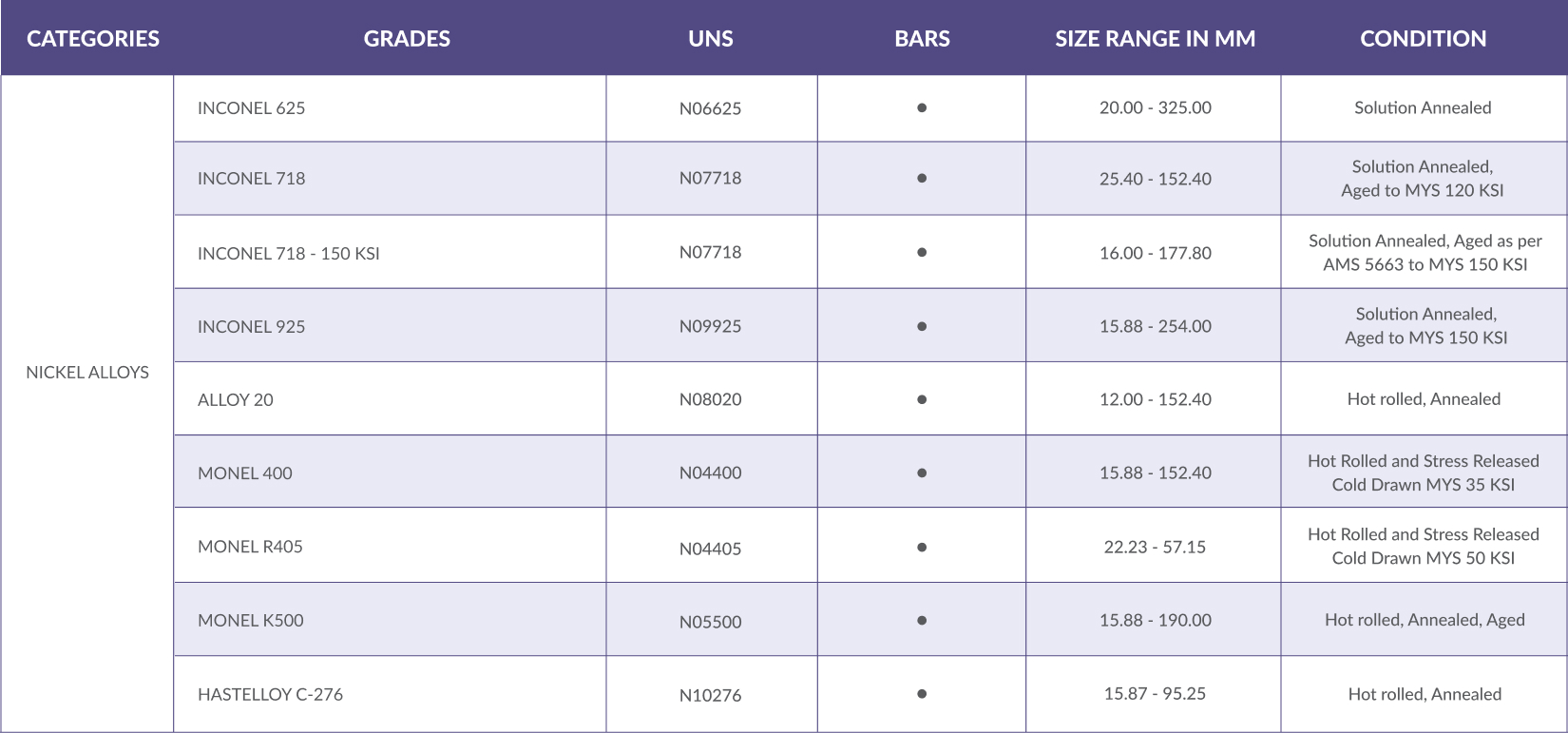

AVAILABLE TYPES

QUALITY ASSURANCE

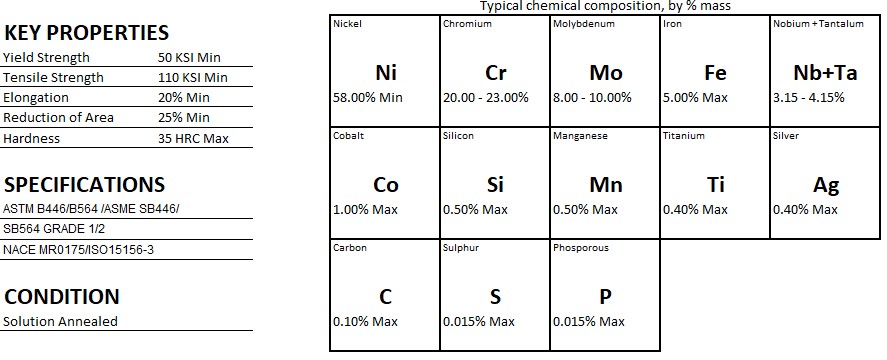

INCONEL 625 (UNS N06625)

Alloy 625 is a Nickel-Chromium-Molybdenum alloy with high strength and toughness from Cryogenic Temperatures up to 1500°F. It has excellent resistance to a variety of corrosive environments but yet possesses excellent fabricability resulting in it commonly being used in sea-water applications and in the field of aerospace. Some common uses for these are Aircraft ducting and exhaust systems, bellows, multiphase flow meters and many more.

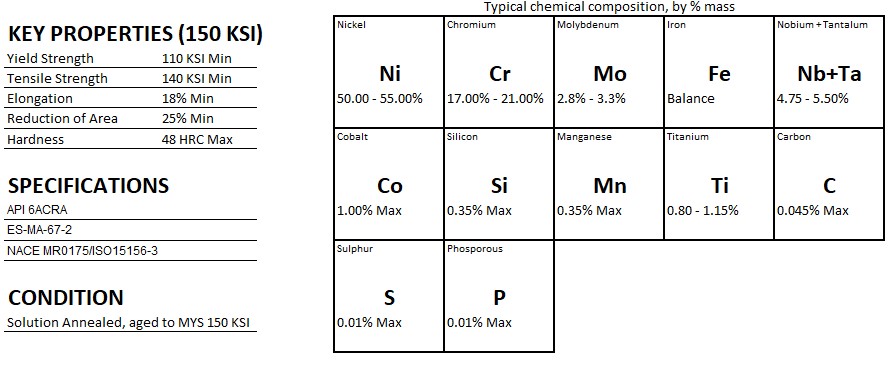

INCONEL 718 (UNS N07718)

Alloy 718 is a high strength, corrosion resistant Nickel-Chromium alloy used for cryogenic temperatures up to long term service at 1200°F. Its ability to be fabricated and combined with goo tensile, fatigue, creep and rupture strength has resulted in its use in a wide range of applications. It is widely used in oil & gas and in the field of aerospace such as for sheet metal parts for aircrafts, land-based gas turbine engines and cryogenic tankage.

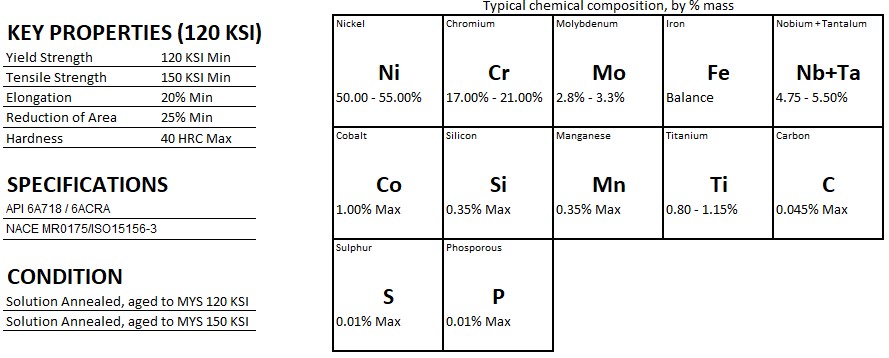

Below is the typical chemical composition for Alloy 718 that has been aged to MYS 120 KSI:

INCONEL 925 (UNS N09925)

Alloy 925 is an age hardened Nickel-Iron-Chromium Alloy with additions of Molybdenum, Copper, Titanium and Aluminum. It has corrosion resistance similar to Alloy 825 but with higher strength obtained through age hardening.

Alloy 925 is used in various applications requiring a combination of high strength and corrosion resistance. This is due to its properties of having good resistance to sulfide stress cracking and stress corrosion cracking in sour (H2S containing) crude oil and natural gas. It is commonly used for gas well components, valves and high strength requirement piping systems.

ALLOY 20 (UNS N08020)

Alloy 20 is a Nickel-Iron-Chromium austenitic alloy designed specifically to withstand sulfuric acid. Alloy 20 is an excellent option when chloride stress corrosion racking is an issue. It also has good resistance to pitting and crevice corrosion. Although originally designed for use in sulfuric acid related industries, Alloy 20 is now a popular choice for a wide variety of industries including the chemical, food, pharmaceutical, and plastics industries.

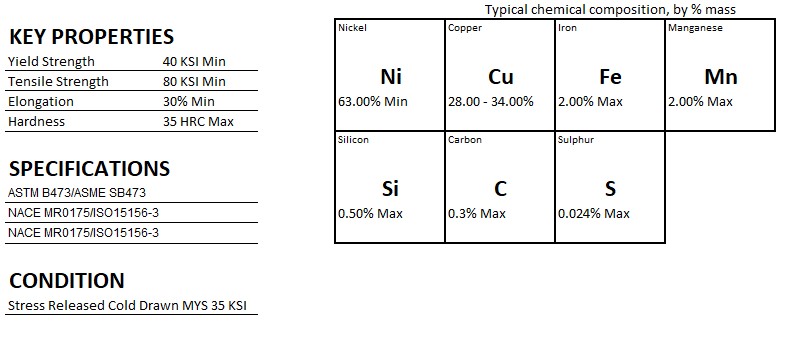

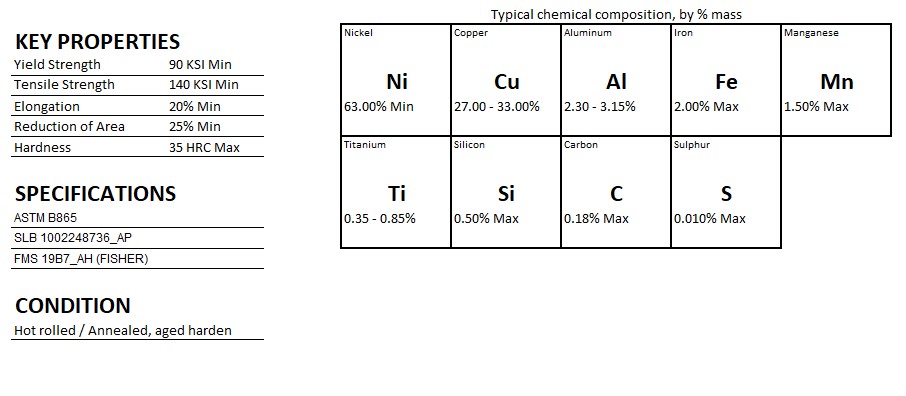

MONEL K500 (UNS N05500)

Monel K500 is a precipitation-hardenable Nickel-Copper alloy that combines the excellent corrosion resistance characteristics of Monel 400 with the added advantage of greater strength and hardness. These amplified properties, strength and hardness, are obtained by adding aluminum and titanium to the nickel-copper base and by age hardening. Typical applications for Monel K500 products are oil well drill collars and instruments, pump shafts and impellers, non-magnetic housings, safety lifts and valves for oil and gas production.

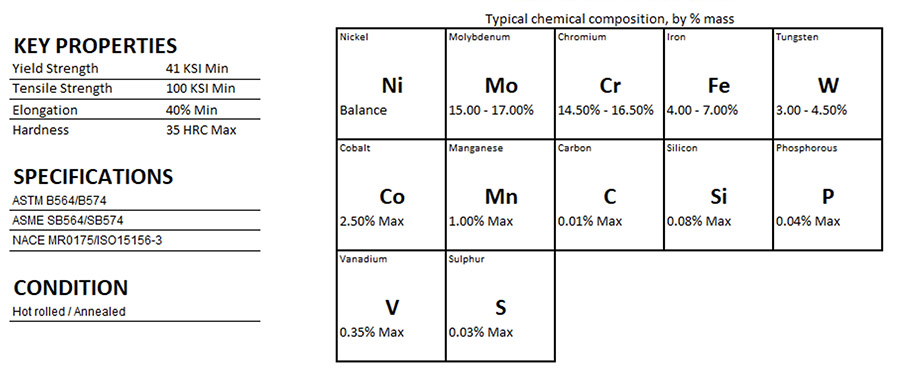

HASTELLOY C-276 (UNS N10276)

Hastelloy C-276 is a Nickel-Molybdenum-Chromium Alloy with the addition of Tungsten. It has excellent corrosion resistance in a wide range of corrosive media and is especially resistant to pitting and crevice corrosion. It is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process application in an as welded condition.